far too little considered by architects and

far too little considered by architects anddesigners. It is still viewed and processed

like a normal concrete.

Our view is more that we design and

manufacture UHPC to treat it more and more

like metal. UHPC in the right quality can

already be machined with tools from the metal

industry. Very high accuracies can be achieved

here whether in surface processing or in shape

processing.

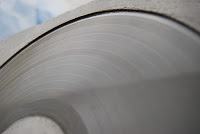

The surface treatment can either be carried out

using special UHPC casting molds or by

identical processing steps as for metals, or

combined casting and subsequent processing.

There are no limits to the design options here.

In terms of shape, metalworking tools or machines

can be used with the same objective as metals.

used a fraction of the technical possibilities.

One example is the use of computer-controlled

water jet cutting machines. For a customer, we

should test the possibilities of making special

bevel cuts as plate slots that cannot be cast in

this way. Additional cutting tests were carried

out to check which geometries can be cut and

what minimum wall thicknesses can be achieved

between the individual cuts. With the right

combination of UHPC binder, unit quality and

setting of the cutting machine, amazing results

can be achieved. The tested UHPC plates had a

plate thickness of 15 - 25 mm, no metallic

reinforcement and were dried for 48 hours in

normal ambient temperature before they were

processed.

With the UHPC binder-aggregate combination

used in the test, cutting distances of 5 mm could

be achieved.

As soon as possible, further cutting tests will be

carried out with UHPC desert sand binders.

Water jet cutting enables complete "images" to be cut in UHPC panels or special construction elements.

With this type of material / machine technology, it is possible to produce a large number of facade panels with an elaborate cut design at low cost in a short time.

WPE DK International

Phone: 0049 176 601 73146

E-mail: ber@wpe-dk.dk

Homepage: www.wpe-dk.com