Many facades of public buildings such as

train stations, airports, banks, administrations,

etc. have almost incredible design in addition

to the necessary thermal function.

Then there are the steel and glass facades,

admittedly they fulfill their function perfectly,

but that's pretty much all that can be said

about them. And there are the old facades

that have aged with pride, which are made of

stones with some figures that bear history.

Each of these facades can tell a story, which

one can certainly not say of glass and steel

facades.

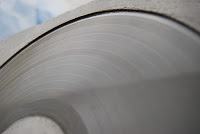

UHPC concrete can perfectly combine the

modern with the proud old design. UHPC

concrete is a modern material for the future

with incredible properties. It offers flexibility

in design, security in temperature and wear

resistance, durability in extreme strength and

very high resistance to almost all environmental

influences, detail in design, easy to use

compared to other materials, it can be processed

on site worldwide.

Facades of houses and balconies were almost

always characterized by their marked simplicity.

For some years now, more and more architects

and designers have been dealing with this area

and also because of the climate discussion.

Today you can see more and more interesting

solutions for facades and balconies of residential

buildings. Simple smaller and larger rectangular

balconies are disappearing more and more and

are being replaced by new balcony geometries.

The old idea of greening facades is increasing

in urban centers. Today it is called the vertical

garden. In the course of this development, the

balconies also became gardens and, for some

architects, veritable forests.

Here too, UHPC concrete offer architects and

designers a variety of new technical and design

options. Due to the extremely high strength

values, balcony slabs can be made much thinner

than with a standard concrete or the balcony area

can be increased significantly with the same slab

thickness as with a standard concrete. As with

the facades, in addition to the strength, the

extremely high resistance to environmental

influences and the resistance to fire is a factor

of great interest.