For more than 25 years, UHPC Ultra High Performance concrete has been used for the construction and repair of concrete bridges worldwide. The mechanical and durability

properties are absolutely ideal for modern bridge construction.

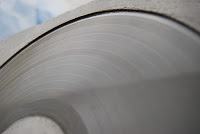

WPE DK UHPC concrete is used in the production of precast concrete parts and for on-site assembly. With UHPC concrete, very slim and high load-bearing elements can be manufactured quickly, cost effectively and very precisely. All of our UHPC material qualities can be processed with most types of concrete mixer.

Our UHPC bridge material qualities are usually mixed with a water / cement ratio of less than 0.25 and a proportion of steel fibers. Compressive strengths of 150 MPa / 21800 psi to over 230 MPa / 33400 psi are achieved in our standard quality.

Our UHPC material properties meet all required technical data, including in the USA from the responsible DOTs. All of our UHPC material qualities are subject to a permanent quality check of the raw materials used, finished products and processing on site on the construction site.

We manufacture UHPC Mortar, UHPC Castable, UHPC Shotcrete and UHPC Rapid material qualities for bridge construction. At the customer's request, we also develop and manufacture special qualities.

UHPC mortar, UHPC Shotcrete and UHPC Rapid are mainly used for repairs. No extensive preparatory work is necessary for repairs with our UHPC materials. After less than 48 hours, our standard materials reach more than 70% of their maximum strength. UHPC is waterproof from a layer thickness of 5 mm.

We use our UHPC TopLayer or UHPC Phalt material qualities for bridge decks. In Europe we use UHPC TopLayer for new wood bridge construction. All UHPC can be mixed on site and processed quickly and inexpensively with standard processing machines.

The mixing is very simple. You mix 1 part UHPC Binder with 1 part aggregates and clear water, that is all. Everybody can mix it. No additional addives are necessary.

Phone: 0049 1514 6318334

E-mail: info@wpe-dk.dk

Homepage: www.wpe-dk.com