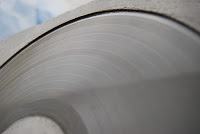

UHPC linings of all kinds of pipes inside and

out was one of our first major projects more

than 25 years ago. The pipes should be

permanently protected against wear and

corrosion with UHPC under the toughest

conditions. First of all, pipes for pneumatic

material delivery lines in the cement industry

were lined. After that, pneumatic and hydraulic

pipelines for the coal-fired power plant industry

and the steel industry were lined. Later came

the offshore industry and the wastewater

industry. We lined pipes of any diameter from

40mm / 1,57inch to 8000mm / 315inch. Here,

the geometry played no major role, so

whether Y-piece, pipe bend, reducer, etc.

The huge advantage of UHPC over all liners at

that time was the seamless lining, the flexibility

in layer thicknesses, the variations in material

quality and the very high wear and corrosion

resistance for a very long service life. Even

today, pipes are in use that were lined 25 years

ago with UHPC.

Today, new pipe systems are lined with UHPC

or existing pipe systems are repaired with UHPC

material. It makes only a very small difference

whether they are concrete or steel pipes.

We use UHPC mortar, UHPC castable and

UHPC shotcrete as lining material. UHPC

Rapid material grades are used for extremely

fast repairs.

In the offshore industry, UHPC is used both

as the inner and outer lining of pipelines.

UHPC can also be used underwater. A 15mm

or 0,6inch thick UHPC coating is waterproof

and absolutely corrosion resistant. A UHPC-

lined offshore structure no longer requires

regular corrosion protection coatings. UHPC

is used today as a material for offshore

constructions and offshore foundations

worldwide.

For some years, we use high temperature resistant

UHPC material in the steel industry. Hot gas

temperatures up to more than 1000°C / 1832°F

are no problem here. We also coat hot gas pipe

system with a combination of UHPC and high

performance insulation. This makes it possible

to dispense with stainless steel as a construction

material, which in turn reduces costs enormously.

Wastewater pipelines, storm water drains, storm

water storage systems road drainage systems,

sewage systems and culverts whether made of

steel or concrete, can be easily repaired with

UHPC. It is not necessary to clean the

construction of rust before you start with the

lining. With UHPC Shotcrete, larger pipelines

can be quickly and permanently repaired. Due

to the extremely low rebound of less than 3%,

special cleaning work in the pipeline is not

necessary.

Smaller repairs can be done quickly with UHPC

mortar or UHPC Cast. As UHPC materials

exceed the compressive strength of all standard

concretes by more than once, steel and concrete

pipelines are more resilient after a complete repair.

Advantage of UHPC

Absolutely waterproof

Absolutely moisture resistant

Extremely corrosion resistant

Very high life expectancy

Very good resistance to a variety of chemicals

Very high strength

www.hhbc-consulting.de

info@hhbc-consulting.de

In our fast-moving times, old houses, some of

In our fast-moving times, old houses, some of that is only suitable as gravel material for the

that is only suitable as gravel material for the combine UHPC with a variety of old used

combine UHPC with a variety of old used