UHPC Ultra High Performance Concrete is a material with immense possibilities. WPE DK International has more than 30 years experience in the development, production and industrial applications of UHPC Ultra High Performance Concrete materials. We produce UHPC Mortar, UHPC Castable, UHPC Shotcrete, UHPC Offshore, UHPC Security, UHPC TopLayer und UHPC Wear Protection

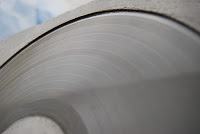

UHPC Wear protection for a KHD Sepmaster cement separator system

Repair of dams and hydroelectric power plant constructions with UHPC concrete

- Very good adhesion

- Waterproof from a layer thickness of 15 mm

- Very high wear resistance

- Very high corrosion resistance

- Very high resistance to frost and ice

- Very good impact resistance

- Quick and easy installation, even of large areas

- Thanks to the extremely fine UHPC binder, even the

- UHPC can be processed as shotcrete, castable or as mortar.

- UHPC reaches more than 70% of its maximum nominal

Especially the slides of a dam are subjected to high amount

In the lake in front of the dam, the dam will be subjected

New build and repair of sewage treatment plants and sewers with UHPC concrete

Sewage treatment plants and sewers are exposed

Sewage treatment plants and sewers are exposedto a permanent chemical and mechanical attack

by sewage from households and industry. Due

to the changing climate conditions and the resulting

extreme rain or flood masses, the systems and

channels are extremely stressed and damage that

their function is no longer guaranteed.

A material with high resistance to chemical and

mechanical attacks is necessary for the maintenance

of these systems.

This material should also be able to be processed

flexibly on site and should not require any complex

machinery.

Damage causes in a sewage treatment plant

- due to mechanical wear

- through frost and de-icing salt

- due to chemical attacks or solvents

- due to concrete corrosion in closed systems

UHPC Ultra High Performance Concrete

UHPC are special concrete products with a minimum

compressive strength of 130 MPa and a water/cement

ratio of less than 0.2.UHPC products can be used very

ratio of less than 0.2.UHPC products can be used verywell for the rehabilitation of concrete - and steel structures.

UHPC products can increase to be rehabilitated

construction next to the corrosion protection even

with admixture of ceramic aggregates the static

bearing capacity.

Benefits of UHPC

- Easy installation as spray, mortar, cast

- Very high corrosion resistance

- Extremely wear-resistant

- Extreme low to no carbonation

- Usable at very high humidity

- Very high impact strength

- Very high impact strength- Extreme low chloride permeabilit

- Very high resistance to mechanical loads

- No pore formation

- Maritime and port water resistant

- Installation in the water possible

- Duration resistant

- The standard drying time is under 48 hours

- Penetrates into the smallest joints and cracks,

and closes them permanently

- Joint less installation

- Very good thermal shock resistance

- Absolutely frost and de-icing salt resistant

Machining UHPC concrete like metals

far too little considered by architects and

far too little considered by architects anddesigners. It is still viewed and processed

like a normal concrete.

Our view is more that we design and

manufacture UHPC to treat it more and more

like metal. UHPC in the right quality can

already be machined with tools from the metal

industry. Very high accuracies can be achieved

here whether in surface processing or in shape

processing.

The surface treatment can either be carried out

using special UHPC casting molds or by

identical processing steps as for metals, or

combined casting and subsequent processing.

There are no limits to the design options here.

In terms of shape, metalworking tools or machines

can be used with the same objective as metals.

used a fraction of the technical possibilities.

One example is the use of computer-controlled

water jet cutting machines. For a customer, we

should test the possibilities of making special

bevel cuts as plate slots that cannot be cast in

this way. Additional cutting tests were carried

out to check which geometries can be cut and

what minimum wall thicknesses can be achieved

between the individual cuts. With the right

combination of UHPC binder, unit quality and

setting of the cutting machine, amazing results

can be achieved. The tested UHPC plates had a

plate thickness of 15 - 25 mm, no metallic

reinforcement and were dried for 48 hours in

normal ambient temperature before they were

processed.

With the UHPC binder-aggregate combination

used in the test, cutting distances of 5 mm could

be achieved.

As soon as possible, further cutting tests will be

carried out with UHPC desert sand binders.

Water jet cutting enables complete "images" to be cut in UHPC panels or special construction elements.

With this type of material / machine technology, it is possible to produce a large number of facade panels with an elaborate cut design at low cost in a short time.

WPE DK International

Phone: 0049 176 601 73146

E-mail: ber@wpe-dk.dk

Homepage: www.wpe-dk.com

HPC Leight weigth and standard products systems for architecture, civil construction and design

In addition to our UHPC offshore, industrial

In addition to our UHPC offshore, industrialflooring, wear protection, security product

systems, we will produce HPC product

systems for architecture, civil construction.

These products will not have the extreme strength

values like the UHPC industrial qualities but have

all the characteristic properties of a high quality

UHPC, such as verygood corrosion resistance,

UHPC, such as verygood corrosion resistance, high early strength development, very good flowability etc.

The new HPC product qualities are:

HPC Leicht 25 Compressive strength 20 - 25 MPa (Lightweight)

HPC Leicht 35 Compressive strength 20 - 35 MPa (Lightweight)

HPC 45 Compressive strength 45 - 50 MPa

HPC 85 Compressive strength 80 - 85 MPa

HPC 135 Compressive strength 130 - 135 MPa

We will offer these HPC qualities in various

packaging sizes, most likely from 25 kg paperbag

to 1 to big bags. We will produce these HPC

products as mortar, castable and shotcrete or as

interieur or exterior plaster.

We can offer private customers as well as

industrial customers all UHPC qualities as

pure binder material or as a mixed material

binder + aggregate.

WPE DK International

Phone: 0049 176 601 73146

E-mail: ber@wpe-dk.dk

Homepage: www.wpe-dk.com

Yearly training semiars for handling of UHPC material

The theoretical lessons taught the knowledge of the

construction site and repair methods with UHPC

materials were also trained.

At a later point in time, training in the processing

of UHPC Phalt (combination of asphalt and UHPC

binder) should be carried out.

It was the first of several seminars and training

program where we provide different UHPC

material qualities for projects free of charge and

also accompany the projects free of charge on

request.

We can also offer seminars for students, which

can then be held at the university or near to the

university.

Universities and students are welcome to contact

questions and information you may have. You can

always reach Anja at a.w@hhbc-consulting.de.

Test your UHPC Know How - Learning Module

This is one of our learning modules for UHPC Concrete. A new version will be released this year. We use such modules for training purposes. New ones are added every year. This year there will be four new modules.

This is one of our learning modules for UHPC Concrete. A new version will be released this year. We use such modules for training purposes. New ones are added every year. This year there will be four new modules. - Cement, microsilica, superplastisizer

- Epoxy, microsilica, dispersant

- Cement, sand, epoxy

- Cement, sand, microsilica

- True

- False

- Only if pH is below 5

- Only if pH is above 5

- Only if pH is below 3

- True

- False

- Only if pH is above 12

- Only if pH is below 12

- Only if pH is above 13

- Quarz

- Bauxite

- Silicium carbide

- Titanium carbide

- Quarz, bauxite, corundum, silicium carbide

- Bauxite, quarz, corundum, silicium carbide

- Silicium carbide, bauxite, quarz, corundum

- Bauxite, corundum, quarz, silicium carbide

- Silicium carbide, corundum, bauxite, quarz

- 20°C / 68°F

- 10°C / 50°F

- 5°C / 41°F

- 0°C / 32°F

- - 5°C / 23°F

- The product cannot seggregate

- The product must remain dry

- There must be free water on top of the product in the mixer

- You cannot add too much water to UHPC

- Any mixing problem can be solved by adding more water

- I contact hhbc-consulting or to have a new bag

- I control the storage environment

- I discard the bag

- I check the date on the bag to see age of product

- No problem, I just add more water

- I wait a while to see if they mix out, if not I will add a little more water

- I throw away the mix

- I check if the mixer is proper prepared for mixing UHPC

- I increase the speed of the mixer

- No problem, Just need to use the product fast

- I allow the mixer to run for longer time, untill the free water is no longer there

- I will try to scoop out the free water

- I throw away the mix

- I add more powder untill the free water disappeares

- It is packing between cement particles, increasing density and displacing water

- It is like little ball bearings making the mortar more flowable

- It reacts with Ca(OH)2 from the cement hydration and create a denser material

- It has no significant effect, just a filler to make the product cheaper

- There is no microsilica in UHPC

- It makes the product more flexible

- It charges all particles so that they repell each other. At the same time it makes stearic hinderence so that particles cannot bridge build on each other, and in this way it displaces water.

- There is no superplasticizer in UHPC

- It is a polymer, added to make the product easier to mix

- It is lubricating the particles so that they can react better

- True

- False

- Sometimes if you are lucky

- Only during the weekend

- Only if you use a special throwel

- Up to 1200°C / 2192°F

- Not above 1000°C / 1832°F

- Not above 600°C / 1112°F

- Not above 400°C / 752°F

- Not above 200°C / 392°F

- Up to 1200°C / 2192°F

- Not above 1000°C / 1832°F

- Not above 600°C / 1112°F

- Not above 400°C / 752°F

- Not above 200°C / 392°F

- True

- False

- Only acid or alkalies

- Especially if there are salts present

- Only if temperature is above 100 deg C

- No problem, I just add more water

- I wait it out for a while to see if it wets through, and I adjust the water accordingly

- I throw away the mix

- I ignore it

- Cross my fingers and hope everything will be ok

- Nothing, you can add as much water as you like

- The product will most likely seggregate, but properties will in general be reduced in direct correlation with the amount of water added.

- Especially if we are working with a UHPC Cast product, installation will be a lot easier

- Strength will increase as we will hydrate more cement

- The stickyness of the product will increase a lot

- It is the same, no difference

- UHPC is stronger in terms of compressive strength

- UHPC is more dense

- Concrete is more flexible

- UHPC can be installed under water

- It i the same, no difference

- Refractory needs heat to finalize its reactions, UHPC does not

- UHPC is more wear resistant

- The insulation properties of UHPC is better than that of refractory

- UHPC can withstand higher temperatures compared to refractoriesWPE DK International

Phone: 0049 176 601 73146

E-mail: ber@wpe-dk.dk

Homepage: www.wpe-dk.com

Roman roads and modern roads construction system

|

| Old roman road |

from our office. As the name suggests, this

road was built by the Romans.

Expert estimates the completion of the road,

approximately 100 km long, in the year

200 AD. This road is about 1820 years old

and is still used as a country road today,

despite a large number of local European wars

and two world wars in these 1820 years. The

structure of this Roman road was never changed,

|

| Roman road structure |

asphalt layer.

If we look at our "state-of-the-art" roads in

most countries of the world today, it can

easily be said that none of these roads will

last for a century. In many cities, the

pavement lasts less than 10 years and in

some highly developed countries of the

world, the pavement lasts less than a year.

Sad but true.

What was important for these Roman streets?

It was the underground structure and the road

surfaces that have survived these roads for so

long. The Romans already knew concrete, but

not only as a road surface, but also as part of

the underground structure.

|

| Roman road today |

high quality road surface, modern roads cannot

get better but only worse than the Roman roads.

UHPC road surfaces, whether as UHPC concrete

or as UHPC Phalt surfaces, are extremely resistant

and are far superior to all previous road surfaces,

but they still need a correct, stable substructure.

This quality underground structure is particularly

|

| Modern road structure |

important for industrial roads and industrial storage

areas.

The interesting thing is that the layer thickness of

a modern, efficient road construction corresponds

in its total layer thickness to that of Roman roads.

WPE DK International

Phone: 0049 176 601 73146

E-mail: ber@wpe-dk.dk

Homepage: www.wpe-dk.com

Elegant and luxury design furniture made out of UHPC

|

are fascinated by concrete. It is a material

that we believe is much more sustainable

than plastic and also has a much longer

service life than plastic. Concrete is easier

and more environmentally friendly to recycle

than plastic.

Concrete can be used in all climates, even the

most extreme. For some time now, experiments

with concrete have been carried out in space.

It is a possible building material for the extreme

conditions on the moon and on Mars.

The only problem for many designers and artists is the necessary wall thickness and weight. Today, furniture is thick-walled with metal reinforcement. A simple bench without a backrest for two people can weigh up to 1500 kg for some manufacturers. Many tables, chairs, etc. have an enormous weight and cannot be moved by one person. You can not say that the previous concrete furniture is gracious and elegant, it really is not. Apparently old natural stone art elements are copied with concrete today, at least that is how they look.

The architects, designers and artists may not even have the knowledge that UHPC Ultra High Performance Concrete has beenavailable to them for several decades. A concrete material that is extremely strong

and stable but also has a non-concrete flexibility. UHPC is superior to concrete in all areas.

With a UHPC material, designer furniture can be created that was previously only available in terms of wall thickness for metals and plastics.

|

| New concrete design |

UHPC design element could be sunk in the

sea and they would remain there unchanged

until the end of time.

A bench as described above would weigh less than half of concrete with UHPC.

Surfaces of outstanding fine structures can be achieved. Art objects can be produced in an unimagined richness of detail, both large and small, up to the jewelry ring on the finger in which one or more gems are

embedded.

|

| New concrete design |

Furniture could be combined with wood,

metal or glass in a new way.

UHPC is a concrete material that can be

bent in a specific construction.

WPE DK International

Phone: 0049 176 601 73146

E-mail: ber@wpe-dk.dk

Homepage: www.wpe-dk.com

Recycling of old building materials with HPc and UHPC bindersystems

In our fast-moving times, old houses, some of

In our fast-moving times, old houses, some ofthem historical houses, are being brutally torn

down to make room for new, more modern,

larger, higher and often not more beautiful but

more effective new building designs. Very

often there is no time left and there is often no

will to secure the valuable and reusable old

building material.

The end of an old building is a heap of rubble

that is only suitable as gravel material for the

that is only suitable as gravel material for thesubbase material of streets.

The architects in particular could campaign

for the reuse of such materials. It would be

entirely possible to reuse these old materials

in modern design concepts and to save some

valuable raw materials.

This year we will start some attempts to

combine UHPC with a variety of old used

combine UHPC with a variety of old usedmaterials. We are very sure that this is

possible without any problems, both in terms

of statics and construction. Of course, with

UHPC we can copy old materials in

appearance and design extremely precisely,

in some cases this is certainly sensible and

necessary. However, we want to reuse old

materials and hand them over to a new

design function. Even building rubble could

become a very interesting concrete material

in combination with UHPC. We also want

to give architects and designers new design

options using old and ultra-modern materials.

UHPC ThermCombi lining systems

a complicated hot gas line is provided with

We reduced the temperature for the steel

layer was installed on the insulation layer.

The advantage over a traditional refractory

lining is:

- The combination lining was about 60% lighter

in weight than a refractory lining.

- The total layer thickness of the combination

lining was 400% less than that of a standard

refractory solution.

- This meant that the steel pipe diameter was

much smaller than with a refractory lining

and the supports had to carry much less weight.

- UHPC HT wear protection can withstand

wear-resistant than refractory concrete, which

has resulted in a significantly longer service life

UHPC Concrete is an ideal material for tactile design

With UHPC Ultra High Performance Concrete, incredible structures and surface fineness can be achieved

in combination with other technical advantages for the tactile design specialists or architects and designer. Since UHPC is a material from nanotechnology, the finest

particles are processed here which make it possible to achieve

previously unprecedented structures and you can produce these structures in

large and small dimensions with a very low and simple effort.

With UHPC Ultra High Performance Concrete, incredible structures and surface fineness can be achieved

in combination with other technical advantages for the tactile design specialists or architects and designer. Since UHPC is a material from nanotechnology, the finest

particles are processed here which make it possible to achieve

previously unprecedented structures and you can produce these structures in

large and small dimensions with a very low and simple effort. UHPC can push model technology to its limits. Because only the quality

of the model construction limits the possibilities of UHPC concrete.

UHPC can push model technology to its limits. Because only the quality

of the model construction limits the possibilities of UHPC concrete.- the extremely high strength, which makes even the finest

structures stable.

- the fast curing of the material with high early strength

- the very high resistance to almost all environmental conditions

- the asolute seawater resistance

- the extremely high corrosion resistance

- the very good combinability with almost all metals, minerals

- desert sand UHPC concrete

- extreme white UHPC concrete

For the processing of UHPC concrete no special tools or special knowledge are required.

An unusual adhesion and tensile test with UHPC Cast

An unusual adhesion and tensile test with UHPC Cast

A customer asked us to demonstrate the exceptional adhesion and tensile strength of our UHPC Cast binder. Our test idea was also unusual. For this test in our workshop we needed a Monster can, two simple rusty flat irons, some UHPC Cast binder, a few steel fibres and bigbags with different fillings.

The Monster can was cut at the top and bottom and the flat irons were put in without touching each other in the can, then the UHPC cast binder material was filled in. We left the material to harden for 24 hours.

After 24 hours a flat iron should be attached to a crane

hook and at the other flat iron weights of 1to, 2to and 3 to were attached.

The respective weight should hang in the crane hook for at least 2 days

without releasing one of the flat iron from the UHPC.