|

| Old roman road |

from our office. As the name suggests, this

road was built by the Romans.

Expert estimates the completion of the road,

approximately 100 km long, in the year

200 AD. This road is about 1820 years old

and is still used as a country road today,

despite a large number of local European wars

and two world wars in these 1820 years. The

structure of this Roman road was never changed,

|

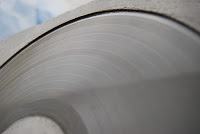

| Roman road structure |

asphalt layer.

If we look at our "state-of-the-art" roads in

most countries of the world today, it can

easily be said that none of these roads will

last for a century. In many cities, the

pavement lasts less than 10 years and in

some highly developed countries of the

world, the pavement lasts less than a year.

Sad but true.

What was important for these Roman streets?

It was the underground structure and the road

surfaces that have survived these roads for so

long. The Romans already knew concrete, but

not only as a road surface, but also as part of

the underground structure.

|

| Roman road today |

high quality road surface, modern roads cannot

get better but only worse than the Roman roads.

UHPC road surfaces, whether as UHPC concrete

or as UHPC Phalt surfaces, are extremely resistant

and are far superior to all previous road surfaces,

but they still need a correct, stable substructure.

This quality underground structure is particularly

|

| Modern road structure |

important for industrial roads and industrial storage

areas.

The interesting thing is that the layer thickness of

a modern, efficient road construction corresponds

in its total layer thickness to that of Roman roads.

WPE DK International

Phone: 0049 176 601 73146

E-mail: ber@wpe-dk.dk

Homepage: www.wpe-dk.com