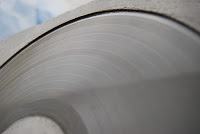

a highly effective insulating layer and UHPC

wear protection layer

For a cement plant in Europe, we should

create a technically optimal possibility thata complicated hot gas line is provided with

wear protection against a very abrasive

material and at the same time the gas

temperature must not drop below 700°C /1292°F. A similar project we had years ago

for a steel plant in Asia.

In order to meet these customer requirements,system.

We reduced the temperature for the steel

structure to 80°C / 176°F. That was no problem

with the insulation material we chose. A high

temperature resistant UHPC wear protectionlayer was installed on the insulation layer.

The advantage over a traditional refractory

lining is:

- The combination lining was about 60% lighter

in weight than a refractory lining.

- The total layer thickness of the combination

lining was 400% less than that of a standard

refractory solution.

- This meant that the steel pipe diameter was

much smaller than with a refractory lining

and the supports had to carry much less weight.

- UHPC HT wear protection can withstand

temperatures of 1200°C / 2192°F, which was

an additional security in this project.

- UHPC HT wear protection is several times morewear-resistant than refractory concrete, which

has resulted in a significantly longer service life

and much less maintenance.

Today, the new UHPC ThermCombi systems are not only used in the steel, power plant and cement industries. The construction industry has also recognised the enormous advantages for building structures and façade constructions. It is not only the insulating properties that save energy, the significantly lower material consumption and the very light precast weight - it is especially the fire and heat resistance that makes UHPC ThermCombi building constructions very safe constructions.